With its all-encompassing solutions, LEAD Intelligent maintains its position as the industry standard in the fast developing energy storage sector. Signing full-line contracts with the top three sustainable energy service providers, LEAD has solidified its position as a major provider of LIB manufacturing equipment and a force to be reckoned with in the global energy storage markets.

Complete LIB Manufacturing Equipment for End-to-End Production

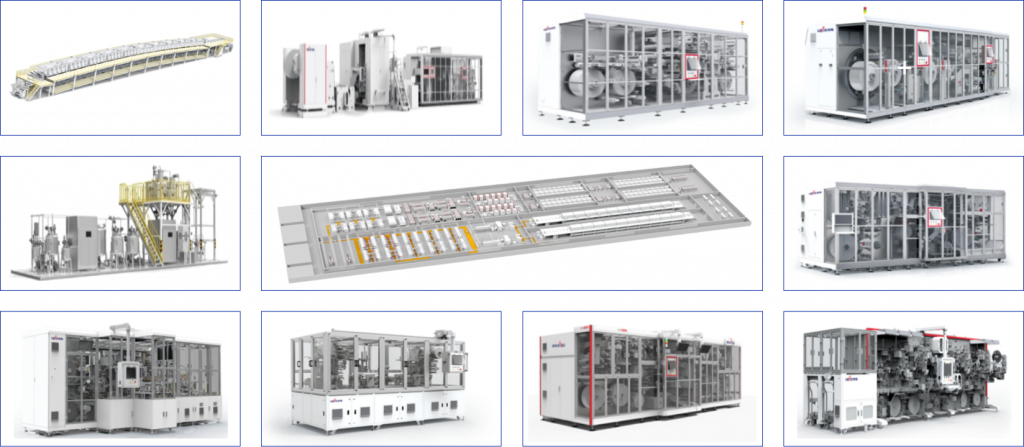

LEAD intelligent‘s LIB turnkey solution spans the entire process—cell production, assembly, testing, and Module/Pack integration. The use of in-house developed LIB manufacturing equipment ensures not just precision but also system-level compatibility across the entire line.

Built-In Intelligence for Smarter Operations

The production line is powered by LEAD’s independently developed MES system, paired with intelligent logistics and warehouse automation. This allows manufacturers to optimize efficiency, track performance in real time, and ensure traceability throughout the battery lifecycle—all through tightly integrated LIB manufacturing equipment.

Reducing ROI and Boosting Performance

By increasing line availability, cycle time, and yield rate, LEAD significantly reduces the return-on-investment period per GWh. The modular design and high availability of the equipment support customers in achieving both cost reduction and operational excellence.

Sustainable, Scalable, and Smart

With a focus on reducing energy consumption while enhancing OEE (Overall Equipment Effectiveness), LEAD Intelligent’s solutions are built for scalability. Every piece of LIB manufacturing equipment is engineered for minimal downtime and maximum performance.

Conclusion

From start to finish, LEAD Intelligent delivers integrated LIB manufacturing equipment that enables energy storage manufacturers to scale faster, operate smarter, and stay competitive in a dynamic market.